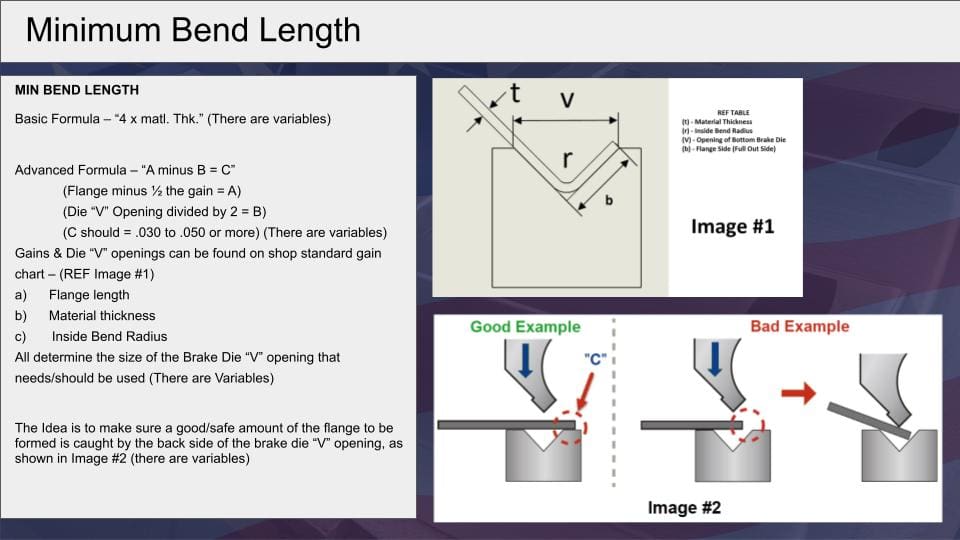

Minimum Flange Length Sheet Metal

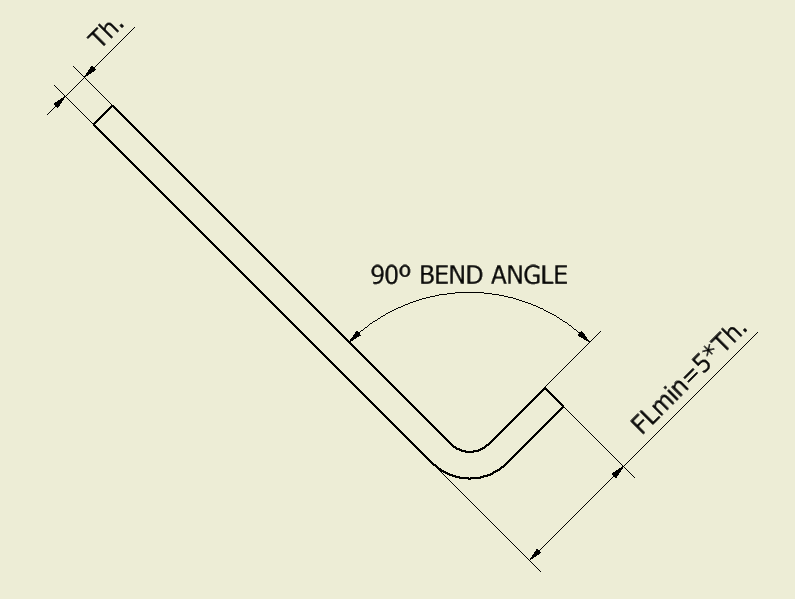

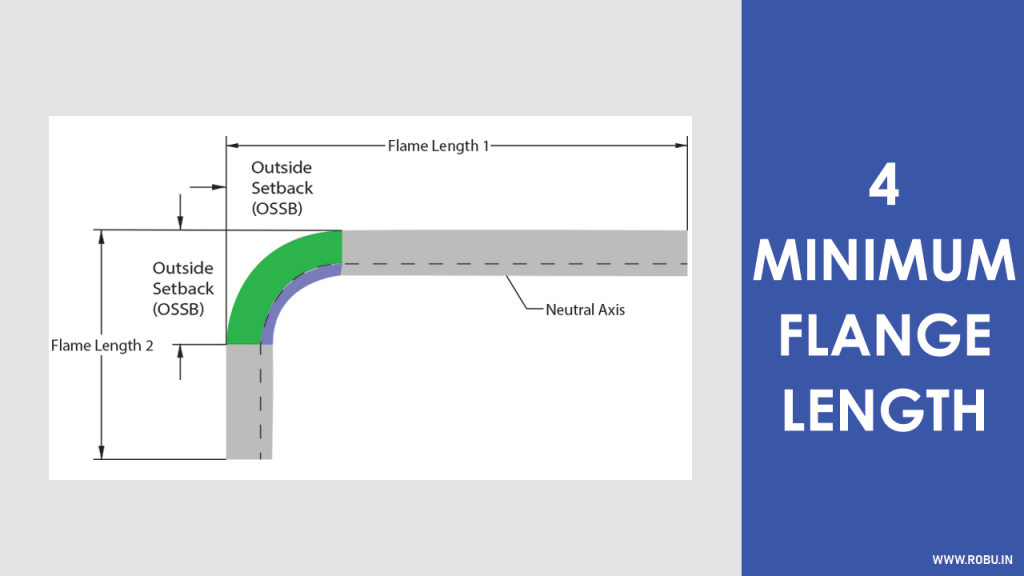

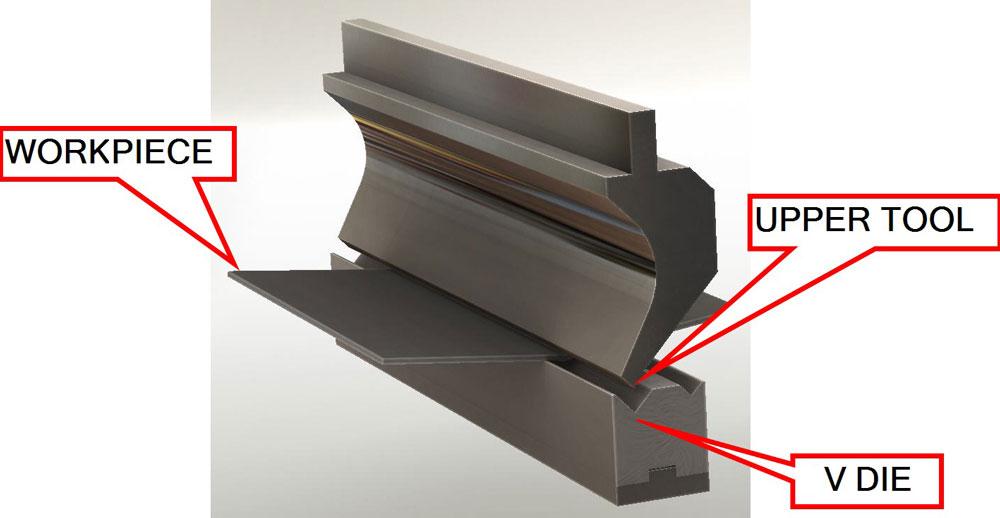

Minimum Flange Length Sheet Metal - The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. A smaller v results in creating a bend. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend. Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius. Minimum flange length on sheet metal parts must be at least 4 times the material thickness. It is recommended to use the same radii across all bends, and flange length must be at least 4 times. Get expert tips and ensure precise results in your metalworking projects.

Get expert tips and ensure precise results in your metalworking projects. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend. It is recommended to use the same radii across all bends, and flange length must be at least 4 times. Minimum flange length on sheet metal parts must be at least 4 times the material thickness. A smaller v results in creating a bend. Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius.

Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend. Get expert tips and ensure precise results in your metalworking projects. A smaller v results in creating a bend. It is recommended to use the same radii across all bends, and flange length must be at least 4 times. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Minimum flange length on sheet metal parts must be at least 4 times the material thickness.

5 Factors Partnering with a Fab Shop (Updated for 2024) ASM

Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake..

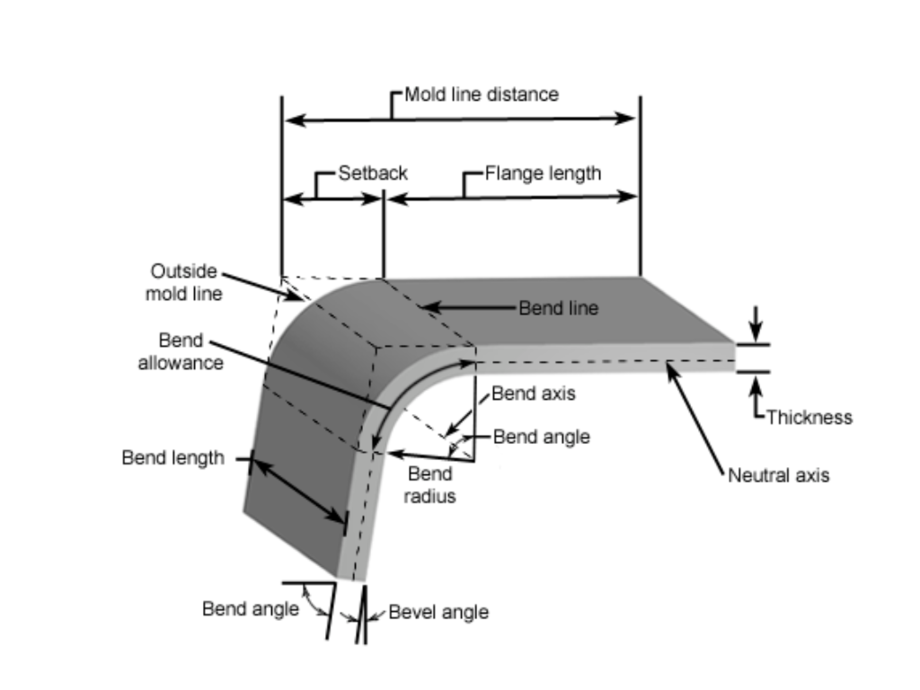

Sheet Metal Bend Radius Full Guide Chart

Minimum flange length on sheet metal parts must be at least 4 times the material thickness. It is recommended to use the same radii across all bends, and flange length must be at least 4 times. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on.

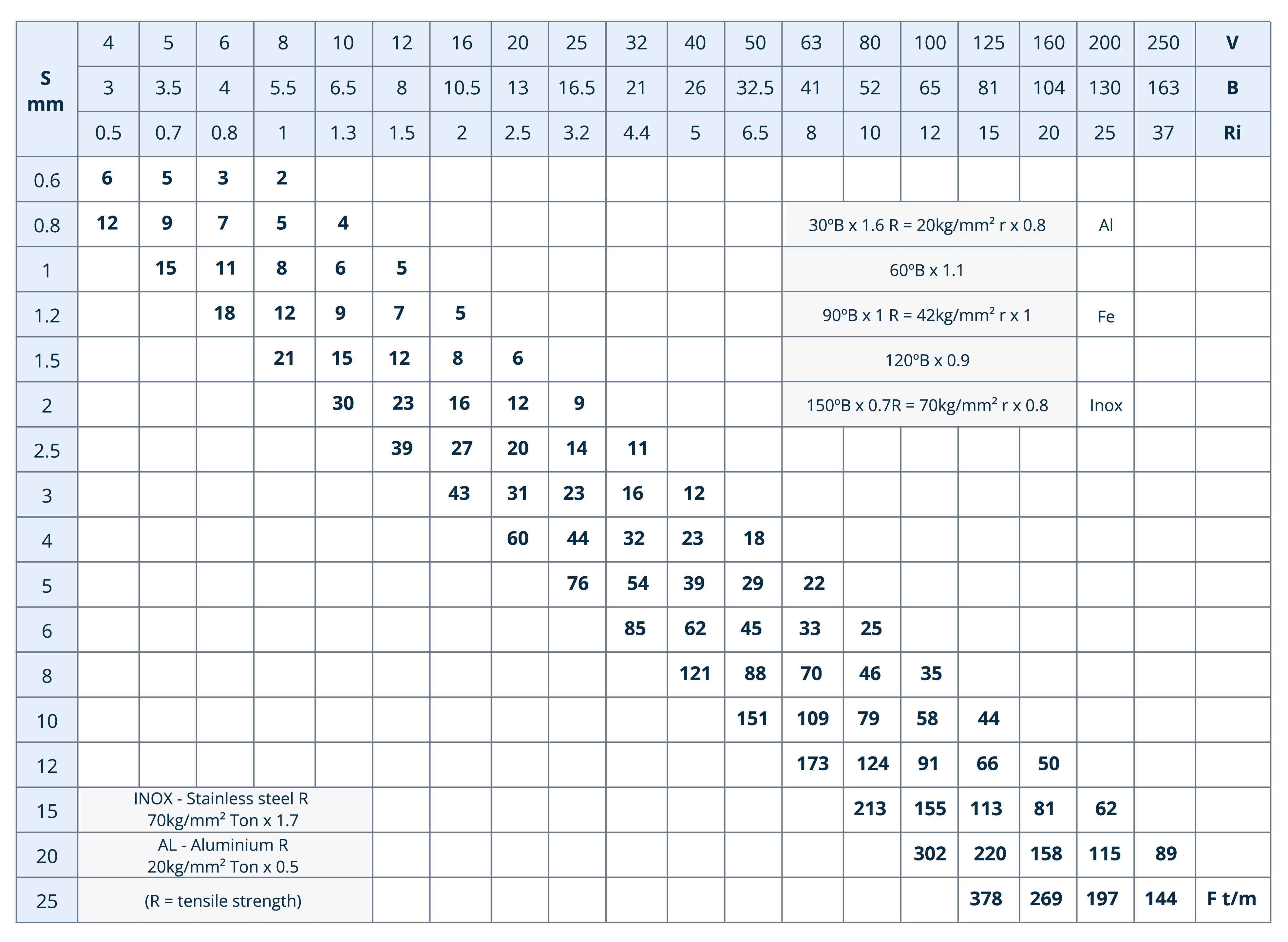

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe

The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend..

Bending short flanges WILA

Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend. Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius. Get expert tips and ensure precise results in your metalworking projects. A smaller.

Mastering Sheet Metal Design First rules to design Cocotubaru srl

Minimum flange length on sheet metal parts must be at least 4 times the material thickness. Get expert tips and ensure precise results in your metalworking projects. Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work.

What to know about sheet metal bend radius and minimum flange

The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend..

Sheet Metal Design Basics in 2021 Complete List of Things

Minimum flange length on sheet metal parts must be at least 4 times the material thickness. A smaller v results in creating a bend. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend. Minimum sheet metal.

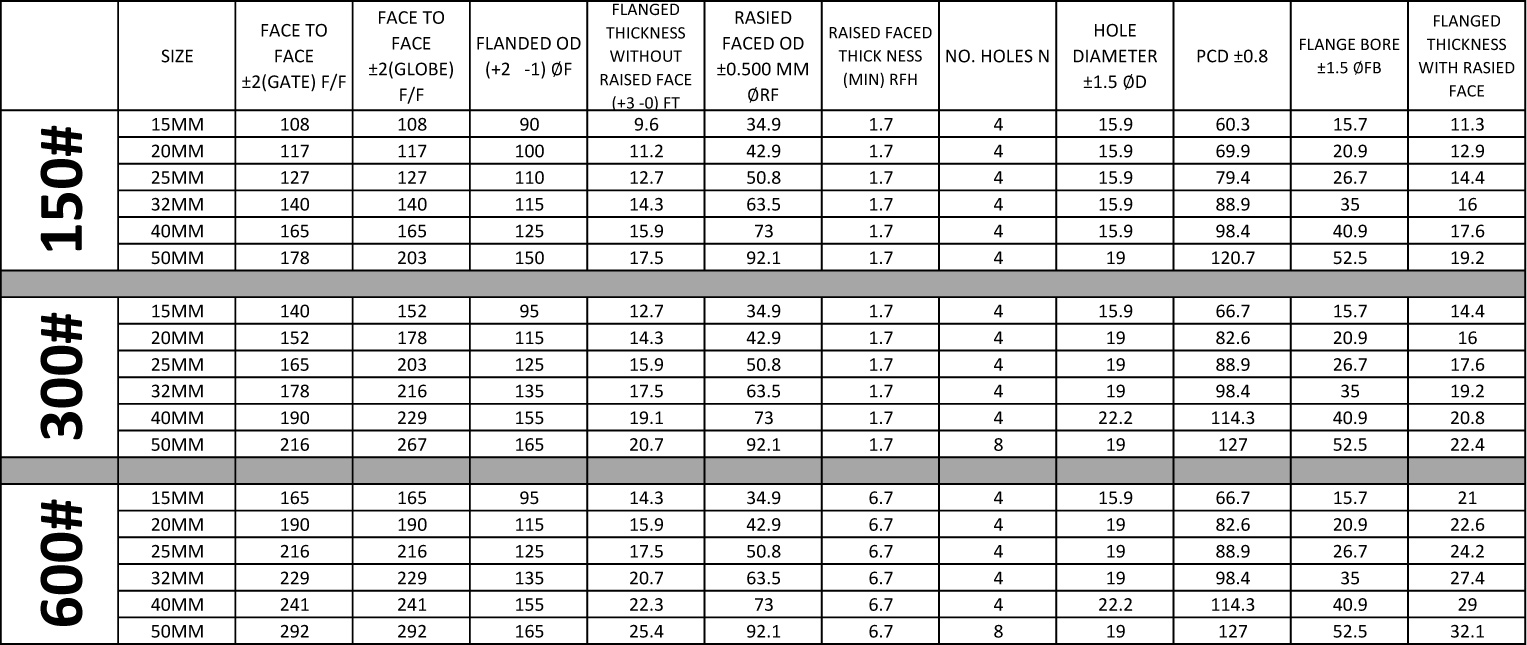

Flange Dimension

Get expert tips and ensure precise results in your metalworking projects. Minimum flange length on sheet metal parts must be at least 4 times the material thickness. A smaller v results in creating a bend. Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius. The upper tool splits that in half, and as a result,.

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal

Get expert tips and ensure precise results in your metalworking projects. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. A smaller v results in creating a bend. Minimum flange length on sheet metal parts must be at least 4 times the.

What sheet metal shops wish you knew Minimum flange, bend radius, and

Get expert tips and ensure precise results in your metalworking projects. Minimum flange length on sheet metal parts must be at least 4 times the material thickness. Brake press operators should know the minimum flange lengths for their tooling before attempting bends that may not work and while it is possible to calculate the minimum flange having an air bend..

Brake Press Operators Should Know The Minimum Flange Lengths For Their Tooling Before Attempting Bends That May Not Work And While It Is Possible To Calculate The Minimum Flange Having An Air Bend.

Minimum sheet metal flange bend length = 3 x sheet thickness + bend radius. It is recommended to use the same radii across all bends, and flange length must be at least 4 times. Minimum flange length on sheet metal parts must be at least 4 times the material thickness. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake.

A Smaller V Results In Creating A Bend.

Get expert tips and ensure precise results in your metalworking projects.